Industrial Steam’s HPR is specifically designed for the corrugating industry. The HPR is engineered to reduce energy use by collecting high temperature condensate from the system and safely pumping it back to the steam boiler without allowing any flash loss. In addition to eliminating flash loss, the HPR increases the efficiency of production equipment by insuring the condensate is properly drained out of the process (and returned to the boilers).

For over 50 years Industrial Steam has successfully helped customers with high pressure/temperature condensate solutions. HPR’s are packaged with deaerators at Industrial Steam’s facility in Atlantic, IA. Only the highest quality components and durable materials are selected when designing and fabricating our HPR systems.

Closed Loop Condensate System

SEQUENCE OF OPERATION:

Steam from the boilers is supplied to all of the corrugators. Steam in the corrugators gives up its latent heat of evaporation, and possibly smallamount of sensible heat. Resultant liquid flows by gravity to the steam traps. As the traps cycle, high temperature condensate flows to High Pressure Condensate (HPR) receiver. Pressure in the HPR is maintained slightly below the lowest steam user in the system to facilitate the flow of condensate from the steam traps to the HPR.

When steam is generated in the boiler, the carbonates decompose and produce C02 gas which is non-condensable. These gases are mixed with steam and enter the corrugator heating units. Since they build up and plate-out on the heating surfaces, the gases must be continuously removed to maintain maximum heat transfer in the corrugator. This is accomplished by the continual removal of steam and C02 through the gas purge line to the pressurized feedwater system. The flow of steam from the HPR to the deaerator is controlled by a modulating control valve. The improved heat transfer will result in an increased production of up to 10%.

Makeup water and all other condensate from the steam system are collected in the pressurized deaerator. The modulating level control on the HPR maintains a constant level with feedwater from the deaerator. Non-condensable gases are vented into the atmosphere.

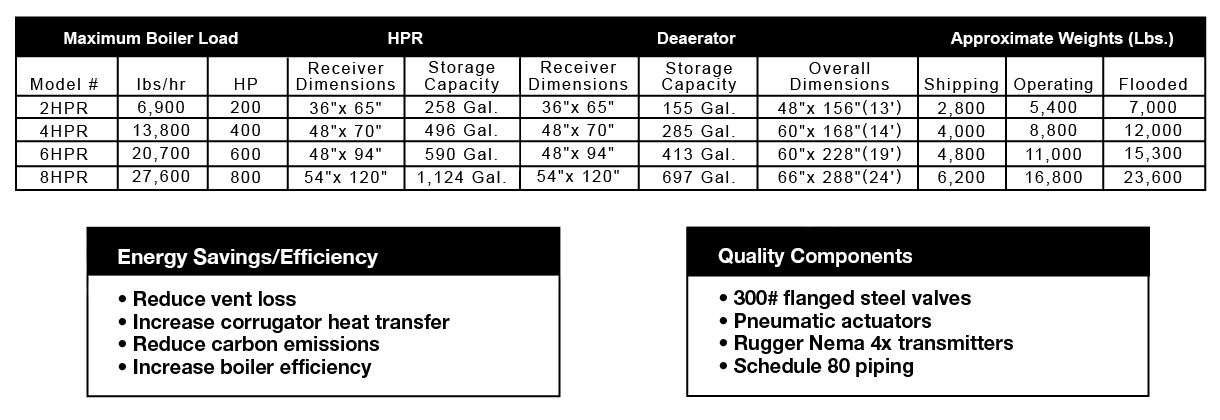

Components and Sizing